Terran R: Our MEDIUM-TO-HEAVY LIFT REUSABLE ROCKET

Government and commercial customers are looking to launch satellites quickly and inexpensively, without waiting for a ride share slot on a large rocket launch to become available. We saw this market gap and set out to design a product to meet our customers’ needs; that’s where Terran R comes in.

Developed for reuse, Terran R will deliver high-volume performance and reliability, with lower costs and shorter time to market. With an iterative approach to design, test, and development, we are able to design and manufacture cost-effective, high-performance, reliable, and reusable rockets. We work at an unprecedented pace and scale, ensuring speed to market for our customers.

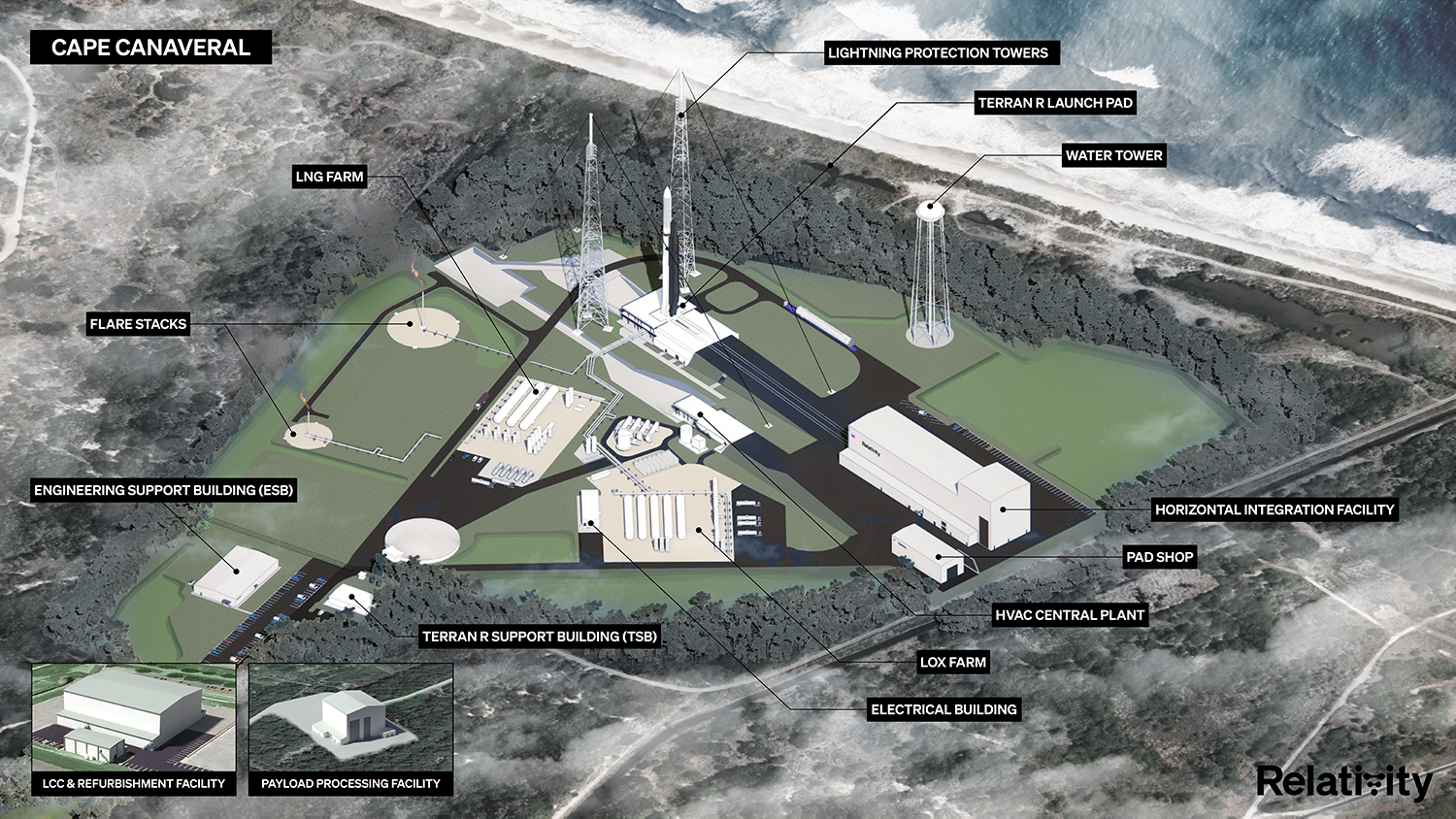

Terran R will launch from Launch Complex 16 at Cape Canaveral Space Force Station starting in 2026.

A fully stacked Terran R rocket beside its reusable first stage

Terran R: Our Approach and Progress

Hear from our leadership team as they break down how we are building and scaling Terran R to meet customer needs.

Terran R Architecture

A Customer-Centric Launch Vehicle

The rocket is 284 feet (86.6 meters) tall, with a 17.7-foot (5.4-meter) diameter and payload fairing. Terran R is designed to meet the needs of commercial and government entities sending payloads into LEO, MEO, and GEO. Terran R will prioritize first stage reusability, with the capability of launching:

23,500 kg to Low Earth Orbit (LEO), downrange landing

5,500 kg to a Geosynchronous Transfer Orbit (GTO), downrange landing

33,500 kg max payload to LEO, expendable configuration

Terran R’s innovative first stage architecture allows for:

High angle of attack reentry which reduces propellant required for reentry burns

Aerodynamic design for better reentry stability and improved control authority

A passively actuated landing leg deployment system which is elegantly simple, lightweight, and highly operable for rapid reuse

A reentry heat shield on the aft end designed for rapid reusability

Designed for Rapid Reusability

Smart Economics for our Customers

Terran R is designed with reusability in mind. Our intent is to design for reuse from the onset, with further development to improve upon this in successive block upgrades. The plan for reuse is as follows:

Shortly after stage separation, Stage 1 will perform a slow flip maneuver using its cold gas Reaction Control System (RCS)

Engines ignite to complete entry burn, slowing velocity and reducing peak loads and heating

Atmospheric entry with grid fin control

Landing burn and passive deployment of command leg slider-mechanism

Touchdown on downrange ship in the ocean

Inspect, refurbish, and recertify for next flight

Bridging the Supply-Demand Gap

The advancement of satellite technology has created launch vehicle demand that cannot be met by current supply. At Relativity, we set out to create a customer-centric rocket to address this gap. Developed for reuse, Terran R has a payload fairing with product-market fit to meet a variety of needs – such as dedicated payload deployments of constellation customers or single geosynchronous satellites to rideshare configurations for multiple customers per launch.

Our Customers and Partners

A testament to our unique approach, we have pre-sold launch service agreements with government and commercial customers totaling more than $2.9 billion. And we’re not alone on this journey; we proudly partner with America’s leading aerospace and innovation agencies to bring launch capabilities to market in record time.

FEATURED CUSTOMERS AND PARTNERS

Iterative Development for Enhanced Performance

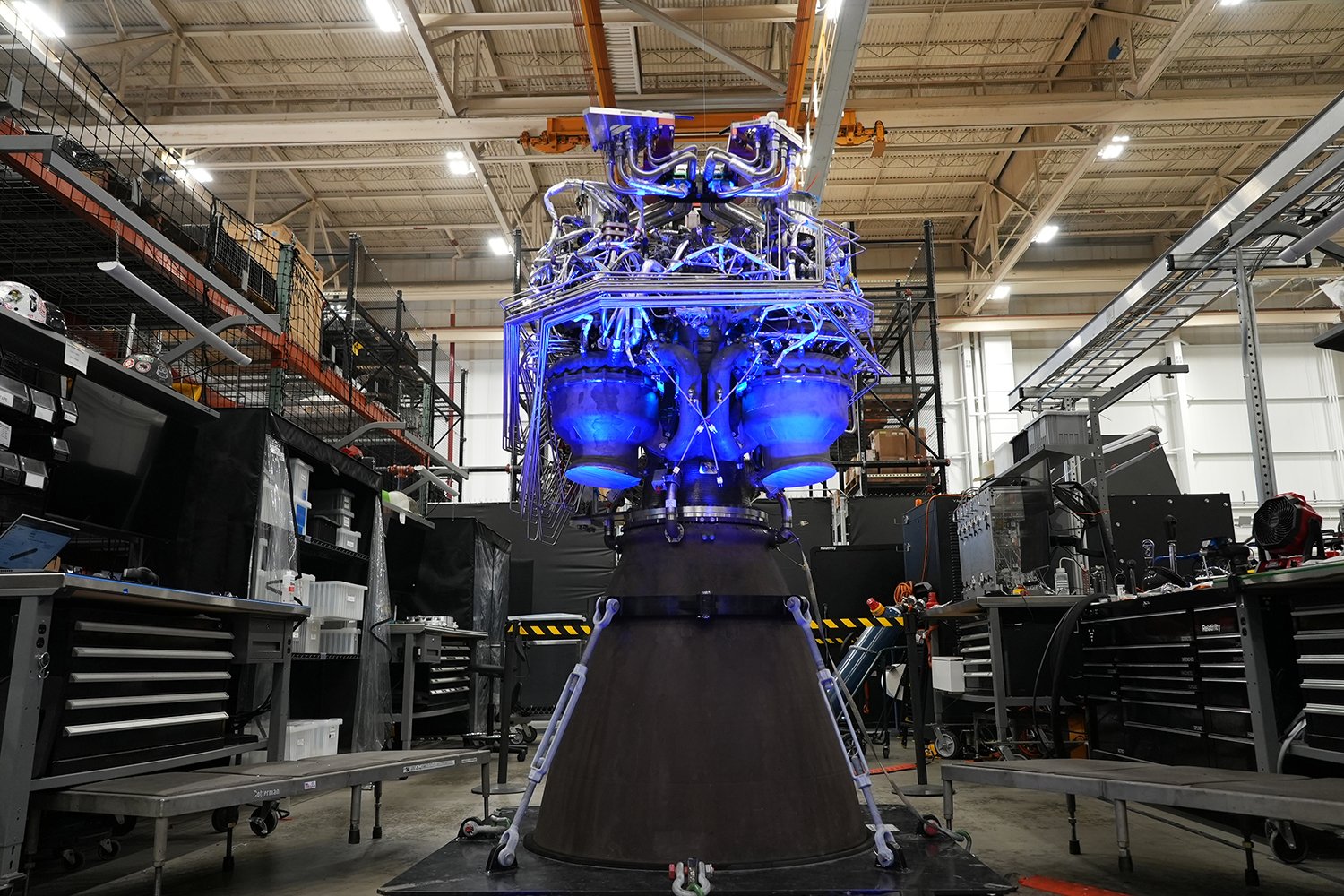

Terran R utilizes our Aeon R engines, built with proprietary 3D printing techniques. Additive manufacturing allows us to design more function into the engines and quickly refine those designs for improved performance and unprecedented testing speed. Through our iterative development process, we progressed from completing a successful mission duty cycle of Aeon R to exceeding the service life runtime required for first stage launch and reuse with a flight-intent engine design in less than a year and half, conducting 2,000+ component and subsystem tests along the way.

STAGE 1

13 3D-printed Aeon R rocket engines

Aeon R sea level thrust of 269,000 lbf for a combined vehicle liftoff thrust of 3,497,000 lbf

LOX/subcooled methane propellants

High pressure gas generator cycle

STAGE 2

One 3D-printed Aeon Vac engine

Vacuum thrust of 323,000 lbf

Subcooled LOX/subcooled methane propellants

High pressure gas generator cycle

Aeon R Testing

Aeon R flight-intent engine gimbaling hot fire – February 2025

Aeon R flight-intent engine hot fire – February 2025

Aeon R gen 3 full duration test with integrated avionics – January 2025

Gas generator component testing – December 2024

Successfully executed combustion stability verification testing – December 2024

Aeon R engine hot fire – December 2024

TCA campaign with upgraded MCC, igniter and injector – August 2024

Aeon R TCA hot fire with full skirt – July 2024

Terran R Program Updates

Terran R’s thrust structure takes shape.

Terran R first and second stage fuel barrels on the factory floor.

Stage 2 common dome meets a stage 2 LOX barrel – the first of many circumferential stir welds.

A stage 2 fuel barrel is welded to a Terran R flight dome.

The first Aeon R qualification engine left Long Beach, CA for hot fire testing in Stennis, MS.

Terran R COPV manifold progress.

Terran R stage 2 barrel removal from the vertical friction stir welder.

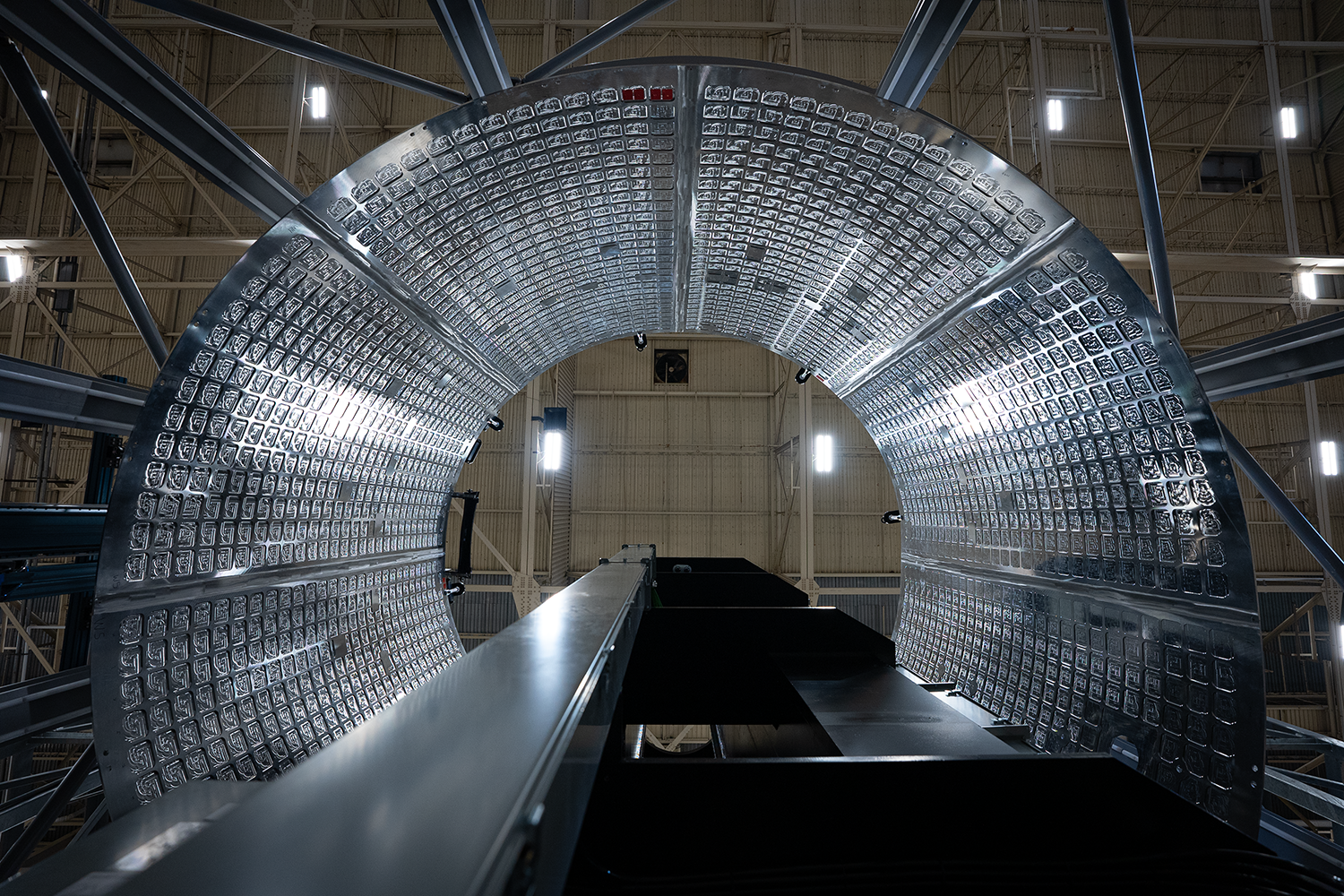

Terran R stage 2 barrel interior orthogrid.

All 6 Terran R first flight domes on the factory floor.

Terran R downcomer stub weld operation onto flight dome.

Terran R thrust structure build in progress.

Terran R composite overwrapped pressure vessels (COPVs).

Upgraded Aeon R engine with full-length sea-level nozzle, and onboard avionics and mechanisms for running flight-intent software for gimbaling engines.

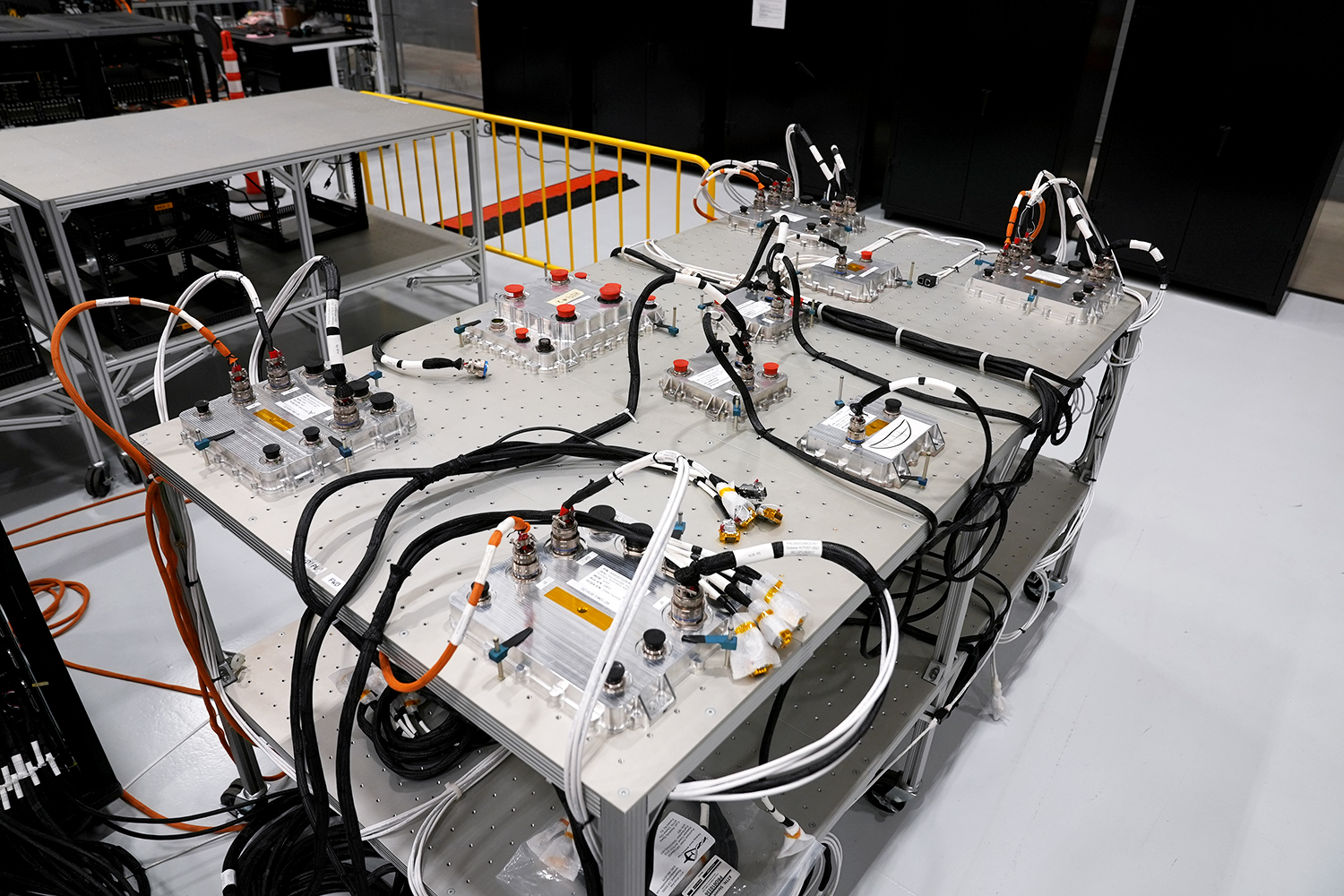

Aeon R components include throttle valves, isolation valves, main valves, and more.

Progress on stage 2 hardware in the loop (HITL) infrastructure and operations.

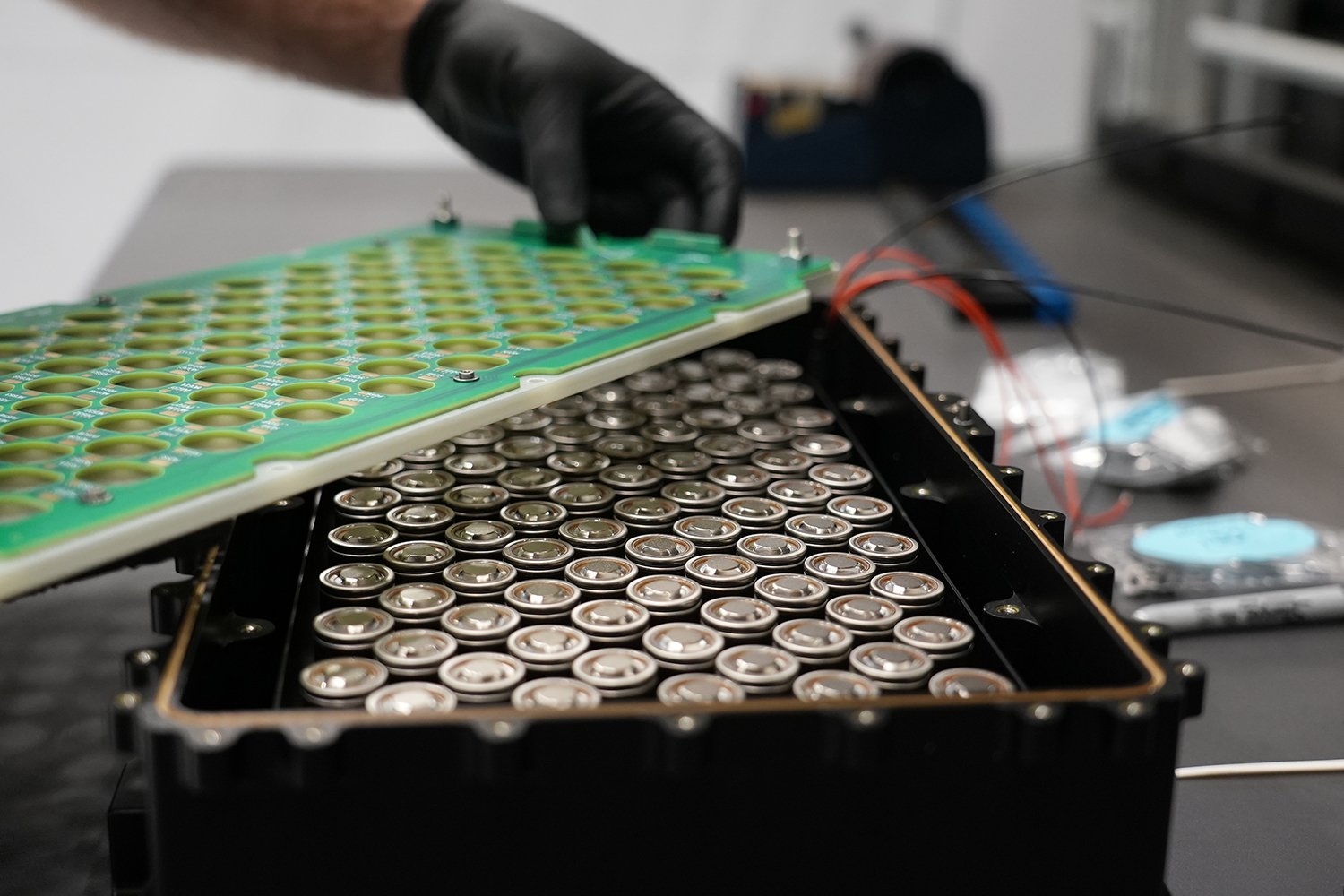

Terran R battery development and production.

Designed and Built in Long Beach, CA

The future is being built at our headquarters in the Los Angeles metro area. Terran R production is underway, and manufacturing infrastructure is being built out to support a high-rate of production.

Tested at Stennis Space Center, MS

Initially used to test key components of the Apollo and Shuttle programs, Stennis has since become a hot bed for a new era of commercial space companies. Relativity occupies the largest footprint of such companies, operating numerous test stands, complexes, and supporting infrastructure.

Launched from Cape Canaveral, FL

Formerly used for the Apollo and Gemini programs, Launch Complex 16 is now being upgraded to support Relativity’s Terran R program. The company has an exclusive site agreement from the U.S. Space Force to use the orbital launch site.