THE FUTURE IS 3D PRINTED

For decades, large-scale manufacturing has relied on fixed tooling. By embracing the potential of additive manufacturing, artificial intelligence, and autonomous robotics, Relativity Space is changing that. We are able to design and produce complex, large-format components to precise tolerances at an unprecedented pace and scale. Rapid iteration allows us to push the boundaries of what's possible today and unlock the full potential of 3D printing for tomorrow.

Factory of the Future

Scalable Technology Platform

Our proprietary Factory of the Future is centered around Stargate, the world’s largest metal 3D printers. This patented approach to additive manufacturing enables innovative structural designs and unlocks an entirely new value chain. With this scalable technology platform, we accelerate our ability to improve design, production, quality, and speed. Our approach enables:

Less fixed tooling and radical reduction in part count

Faster design iteration and part optimization

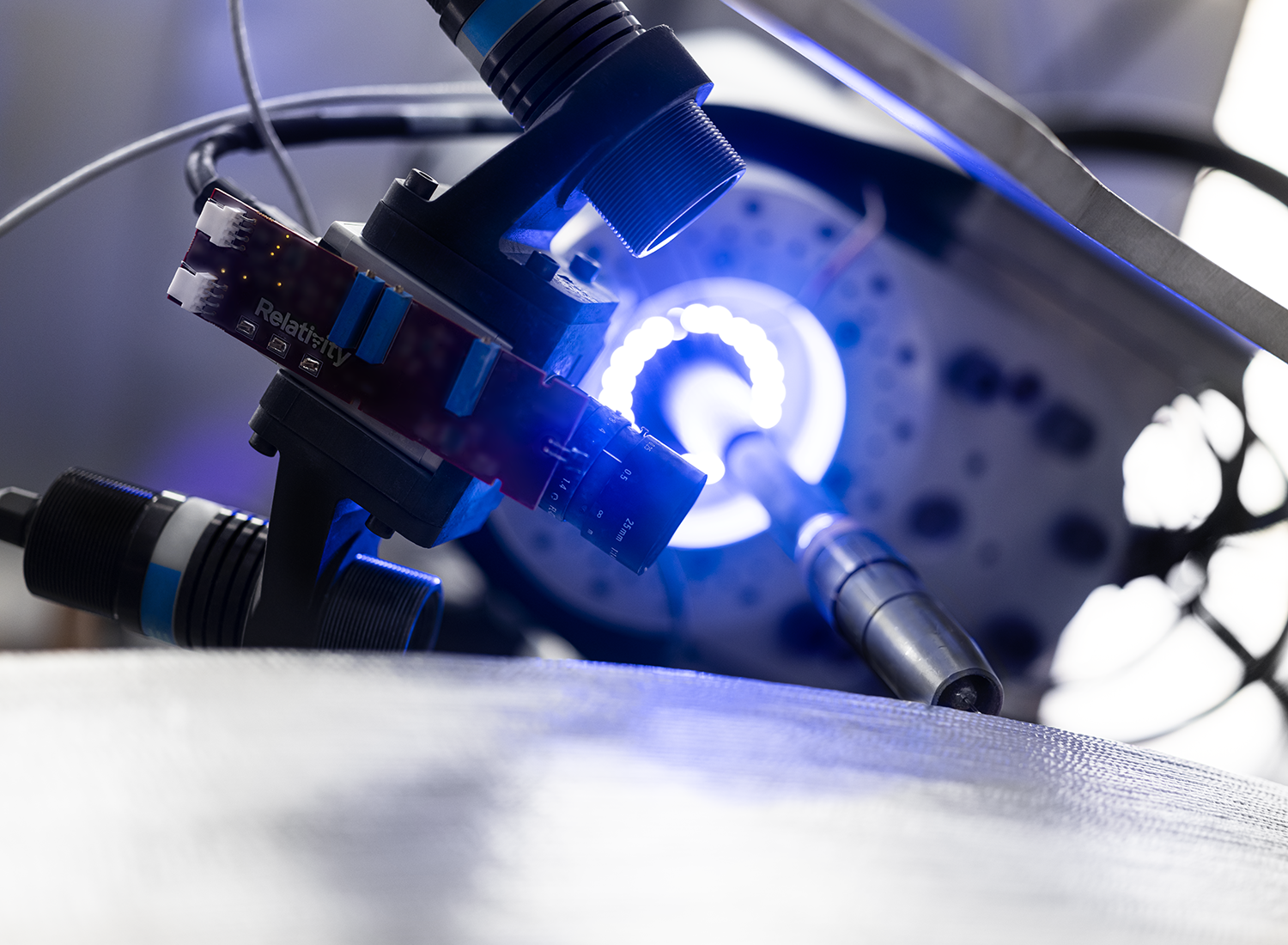

Real-time quality control and inspection

Sensor and analytics-driven machine learning

Stargate 4th generation metal 3D printer

The New Era of Manufacturing

High strength proprietary alloys specially designed for Stargate printers

Physical properties designed to meet mission-critical structural requirements

In-house material characterization lab for quickly iterating on new alloy development

Intelligent data-driven manufacturing

Machine learning control algorithms

Collaborative additive and subtractive process enables complex geometry

Verification and validation data captured during manufacturing

Flexible and highly scalable system architecture

Cloud-based manufacturing simulation and training

Parts are inspected during and after printing to ensure they meet the highest standards of uniformity and quality